1.Overview

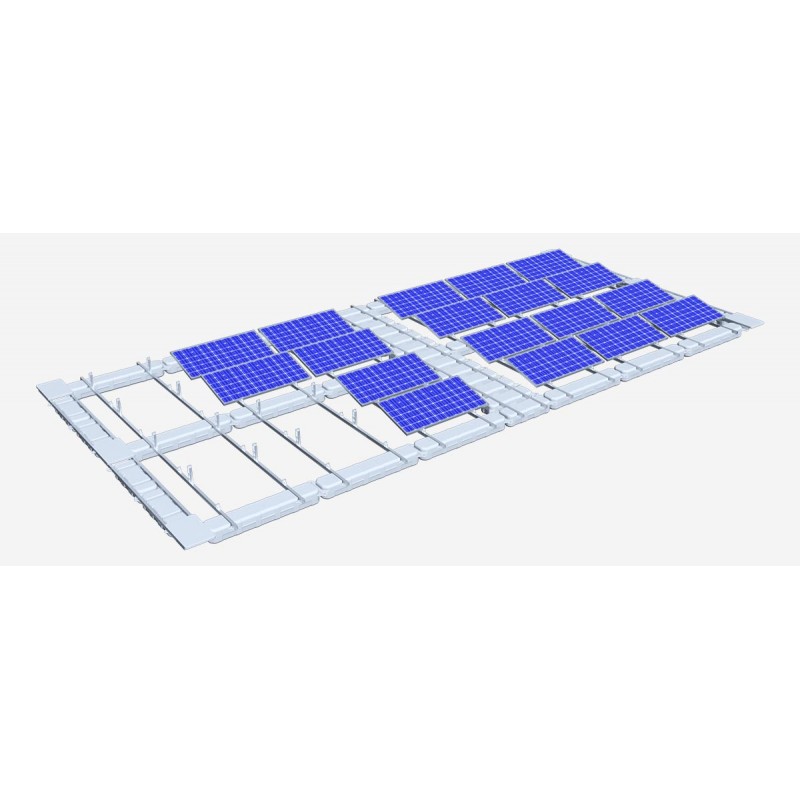

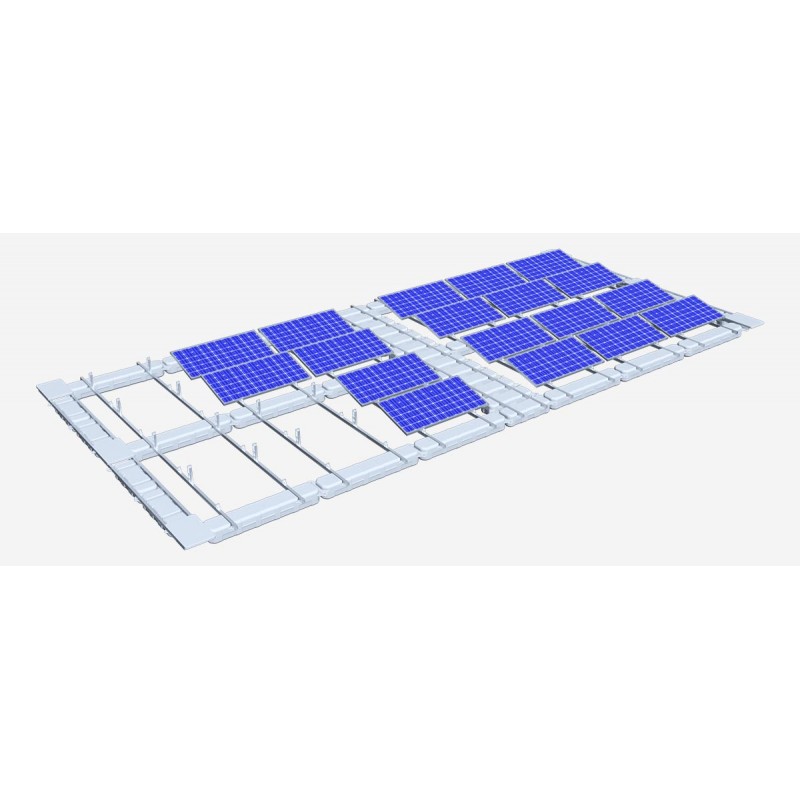

The floating PV mounting solutions from the G5 series can be used in a variety of aquatic environments, including lakes, reservoirs, and coal mine subsidence sites. Brackets and floaters make up the system. High-density polyethylene (HDPE) is the material used to create floaters, and it has benefits including high strength, corrosion resistance, fatigue resistance, a low water absorption rate, and good chemical stability. The materials for the guide rail and bracket can be chosen from among aluminum alloy and aluminized magnesium zinc, which have good anti-corrosion characteristics, are lightweight, and have a beautiful appearance.

Our floaters undergo industry-standard tests for tensile pulling force, aging resistance, UV resistance, air tightness, high and low-temperature cycling, and impact resistance. They exhibit strong weather resistance and have a service life of up to 25 years. The embedded structure is used for fixing between the floaters, ensuring a more stable overall connection. The modular design allows for horizontal and symmetrical arrangement, which can improve water coverage, increase installation capacity, and enhance power generation efficiency.

.jpg)

Floaters (HDPE) and aluminum alloy are used in the G5A track, whereas floaters and aluminized magnesium zinc are used in the G5M track. According to the needs, the arrangement can be created. G5M lowers the height based on the original floaters in comparison to G5A. This maintains buoyancy, guarantees the height of the solar panels above the water's surface and saves cost. It is appropriate for regions with little or no snowfall.

2.Features

1. High-Quality Materials: High-density polyethylene, an environmentally acceptable, non-polluting material with a lengthy useful life, is used to make floaters. The mountings made of aluminum alloy are lightweight, aesthetically beautiful, corrosion- and rust-resistant.

2. Innovative Structure: Modular design with embedded fixing between the floaters; the groove-type structure ensures the maximum fixation of support legs to the components. By increasing the size of individual floaters, the buoyancy of each floater is raised to over 150kg.

3. Various Arrangements: The modular structure supports various array combinations, allowing customized layout schemes according to actual needs, maximizing installation capacity, and power generation.

4. High Safety: The floaters have widened walkways with anti-slip design, ensuring safer installation and maintenance.

5. Adjustable Angles: Installation options of PV mounting with various angles such as 5°, 10°, 12°, and 15° are available to adapt to local sunlight conditions. The mounting system is compatible with solar panels of all specifications.

6. High Weather Resistance: The floaters undergo multiple industry-standard tests and can efficiently and stably operate in various natural environments, including high temperatures, high humidity, high altitudes, sand, dust, and salt spray.

3.Technical Parameters

Installation Location: Lakes,reservoirs, and other water surfaces

Installation Foundation: Floaters, aluminum alloy bracket, aluminized magnesium zinc brackets

Installation Angle: 5°、10°、15°

Wind Load: 60m/s

Snow Load: 0.5KN/㎡

Applicable Module Type: Framed & Double-glass PV modules

Module Layout: Horizontal, same direction, symmetrical half-coverage

Adaptable Maximum Solar Panel Size: 2420mm x 1300mm

Design Standards: AS/NZS 1170,DIN 1055,JIS C8955:2017,

International Building Code:IBC 2009,

California Building Code:CBC 2010

Main Body Materials: HDPE、aluminum alloy

Fasteners: Stainless steel SUS304

Accessories: AL6005-T5 (anodized surface)

Mounting Color: Light gray or custom

Floater Buoyancy: >150KG

System Warranty: 10 years

4.Anchoring Method

G5A , the MRac Floating Mounting System will be fixed using an anchoring system. Usually, underwater anchor points were chosen, but to select above-water anchor points is also feasible. The anchoring system will be designed based on the customer's water area conditions.

.jpg)

.jpg)

5.Technology Certification